수년간, 항공기 동체의 판금 및 성형 부품 생산 노하우및 기술력을 바탕으로 고객의 Needs인 품질및 납기 준수를 최우선으로 관리하고 있습니다.

Over the years, we have put the highest priority on the quality and delivery of our customers' needs based on the know-how and technology of sheet metal and extrusion parts of the aircraft body.

Procedure

고객이 요구하는 품질수준과 제품개발 Lead time 최소화를 위하여 최적화 시스템을 적용하여 개발 및 생산을 진행하고 있습니다.

In order to minimize the quality level required by customers and the lead time of product development, we apply the optimization system to develop and produce.

- 01. Contract

- 02. Part Planning

- 03. Part fabrication

- 04. Quality control

- 05. Tool Design

- 06. Tool insp

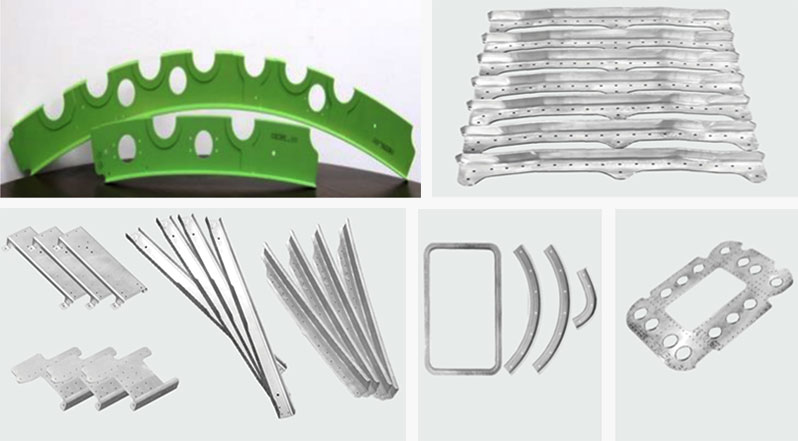

Available part Service

- - Brake forming

- - Hydro forming

- - Stretch forming

- - NC routing

- - Blanking / Piercing

- - Roll forming

Sheet metal parts

- - NC routing

- - Pin routing

- - Hot joggle

- -Stretch forming

Extrusion parts